Motor Circuit Analysis

Detect and diagnose motor faults before they disrupt performance.

Applications Include

Why Motor Circuit Analysis (MCA)?

Motor Circuit Analysis (MCA) is an essential tool for maintaining the health and efficiency of your motor systems. By proactively testing motors with MCA, you can identify faults before they lead to costly downtime and extensive repairs. MCA enables you to make data-driven decisions that extend the life of your motors, reduce repair costs, and keep your operations running smoothly.

- De-Energized Testing for Safe, Non-Destructive Analysis

- Comprehensive Fault Detection Beyond Ground Issues

- Preventative Maintenance for Reduced Downtime

- Accurate and Reliable Motor Health Diagnostics

- Quick and Easy Test Implementation for All Technicians

- Early Fault Detection for Cost Savings

- Thorough Testing with Multiple Key Measurements

Inspection Process

Our MCA inspection process is designed to be quick, thorough, and non-disruptive to your operations. We prioritize efficiency and precision while minimizing any downtime.

Our team works efficiently to complete testing in less than 10 min per motor, ensuring minimal interruption to your operations. We understand that unplanned downtime can be costly, so we offer flexible scheduling options tailored to your specific needs.

1) Daytime inspections

2) After-hours evaluations

3) Assessments aligned with planned maintenance outage

These flexible scheduling options help us accommodate your operational requirements while maintaining thorough testing.

Our technicians are highly trained and qualified professionals, ensuring exceptional service.

- Certified Thermographers: Level II or III certified professionals with extensive experience in industrial applications. They are trained to not only capture thermal images but also to interpret them in the context of your specific equipment and processes

- Acoustic Imaging Specialists: Experts trained in the latest acoustic leak detection and partial discharge identification techniques. They are skilled in using our advanced acoustic cameras and interpreting the results.

- MCA Technicians: Certified professionals experienced in performing de-energized motor tests. They use advanced MCA instruments to detect a wide range of motor faults, ensuring precision and reliability in every inspection.

After completing the test, we provide a detailed report outlining the findings and any recommendations. Our reports are designed to be clear and actionable, helping you make informed decisions. Our technicians are available to review the results with you, answering any questions and offering guidance on next steps.

Long-term Contracts Module

Long-term MCA contracts offer significant benefits, including trend analysis over time, which provides deeper insights into motor performance and potential degradation patterns. These contracts also offer favorable pricing and priority scheduling, ensuring your motor systems are always tested at the most convenient times.

With a long-term contract, we can collaborate with you to develop and implement a comprehensive motor testing plan that aligns with your maintenance strategies, downtime schedules, and budgetary considerations. This proactive approach helps extend the lifespan of your motors and reduce unexpected failures, ultimately leading to greater operational efficiency.

- 1 Year

- 3 Year

- 5 Year

Who We Help

MCA’s precision and ability to detect early motor faults make it a valuable tool for data-driven maintenance strategies across various industries.

By implementing MCA, businesses in these sectors can proactively manage motor health, reduce unexpected downtime, and improve overall system reliability.

- Manufacturing Plants

- Power Generation

- Water Treatment Facilities

- Oil & Gas

- Mining Operations

- Commercial and Industrial Facilities

- Machine Tool Industry

- Transportation & Logistics

Featured Case Studies

Other MSAI Inspection Services

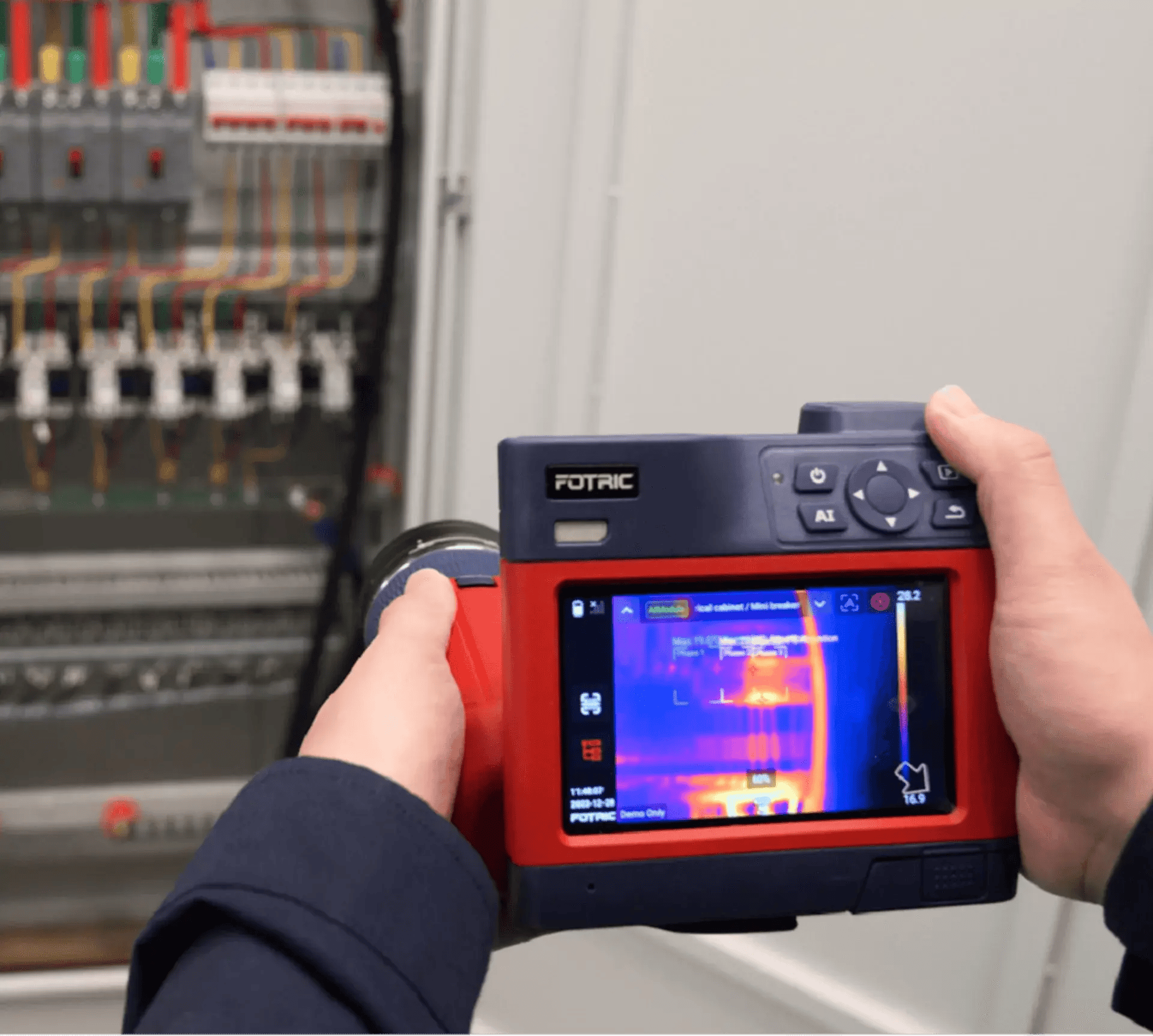

Thermal Imaging

Thermography inspection services enhance predictive maintenance strategies by identifying thermal anomalies, indicative of future equipment failures and/or inefficiencies. Identifying emerging issues early through non-invasive inspections, helps prevent unexpected downtime and costly repairs.

Acoustic Imaging

Acoustic imaging visualizes sound, enabling the detection of air leaks, partial discharges, and other sound-based anomalies in compressed air systems, electrical equipment, and steam systems.

Explore MCA-Compatible Products

Optimize the performance and reliability of your motor systems with our advanced Motor Circuit Analysis (MCA) tools. MCA™ is a state-of-the-art diagnostic method that enables early detection of motor faults, including winding issues, rotor imbalances, and insulation degradation. By conducting non-destructive, de-energized testing, MCA™ helps prevent unexpected downtime and costly repairs, ensuring the longevity and efficiency of your operations.

- AT7 Pro

- AT7

- ATPOL III

- MD III

- AT34

- AT34 EV

- Motor Genie MCA

- And More...

Contact MSAI Inspection Services

Reach out today! Our expert technicians are always happy to answer any questions you might have.